Wagenborg Foxdrill contributes to time-saving special periodic survey on board drill ship Saipem 12000

A significant reduction of downtime

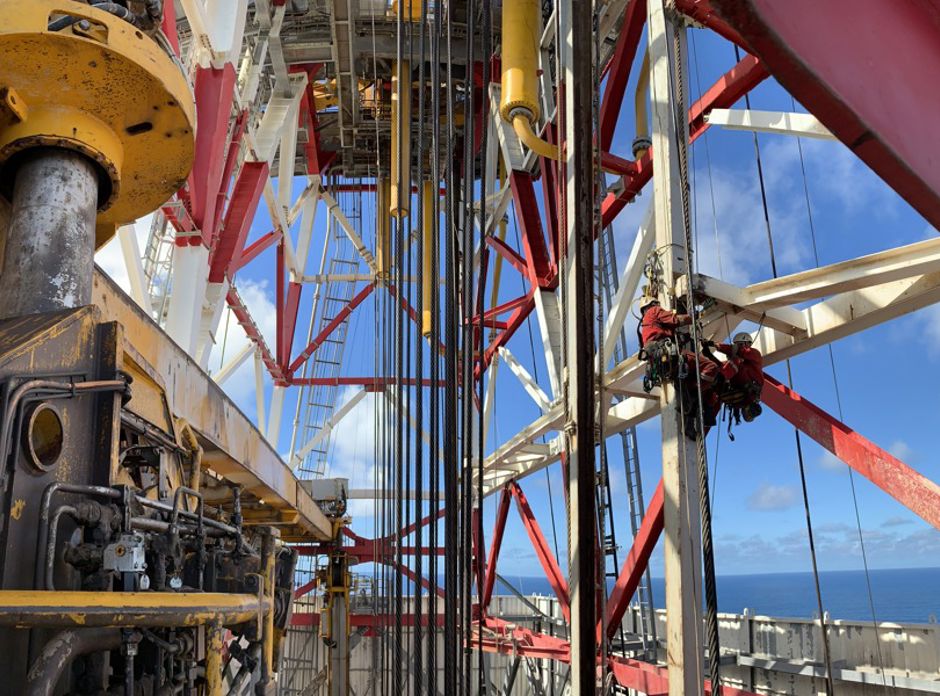

A combined scope was prepared to maximise the added value of Wagenborg Foxdrill’s presence and involvement in the preparations for the Special Periodic Survey. Bart Oude Ophuis explains: “After careful considerations and a risk assessment, we planned a large part of the activities to take place during the sea voyage of the Saipem 12000 from offshore Pakistan to Port Elizabeth in South Africa. For Saipem this meant a significant reduction of downtime and the duration of the overall survey process. However, our team on board faced a challenging feat: most of the inspection activities involved working at height while the drillship was sailing across the Arabian sea.”

For Saipem this meant a significant reduction of downtime and the duration of the overall survey process.

Risk reduction efforts and maintenance strategy

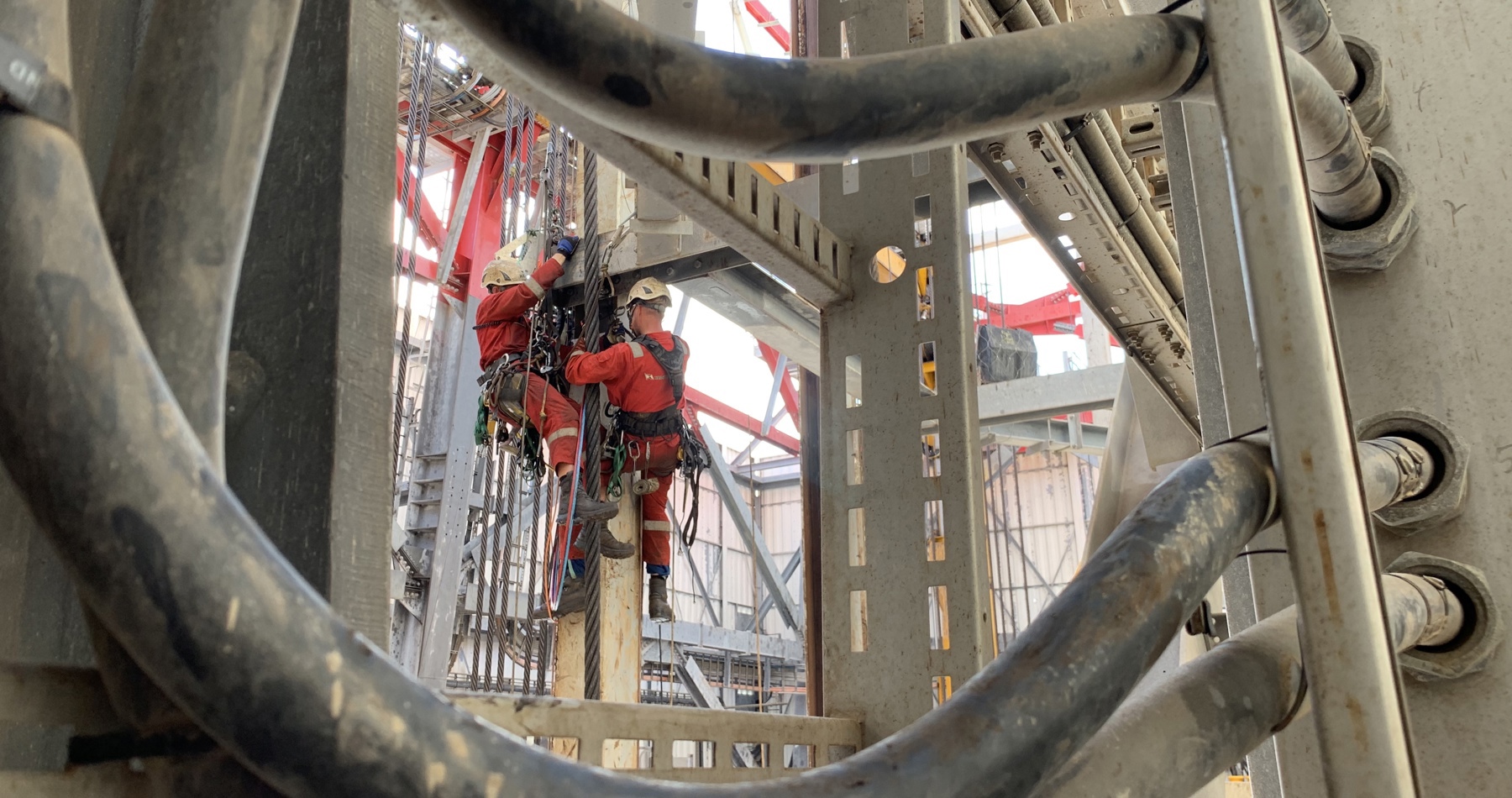

The scope of the first part of the project included a full visual derrick inspection, a bolt tightness survey as well as a Dropped Object Survey. Bart continues: “For this phase, a first team of specialists - led by supervisor Bart Poorthuis – was mobilized to Karachi. They completed their journey with a 20 hour sea voyage to reach the drillships location, 370 nautical miles offshore. Before the team arrived at the drillship, I made sure the specifically selected equipment set was already on location. For this, we airlifted all equipment from Netherlands to Karachi and transported it to the drillship. Upon arrival, our team could start immediately with the various planned inspections and surveys.” Foxdrill team members Bart Poorthuis, Frank Groeneveld, Ferry Snijders, Peter Bornebroek utilizing rigging techniques and rope access to remove and lower the crane’s cylinder. By using rope access and while adhering to strict safety measures, this first part of the scope was completed in time and before arrival at Port Elizabeth. All three activities are part of risk reduction efforts and the maintenance strategy of the Saipem team.

Disassembly and removal of equipment

Upon arrival in Port Elizabeth the first Foxdrill team was relieved by a second team. “In the second phase of the project, the new team – led by rope access team leader Sander Hilbrink - started with partial disassembly and removal of various equipment pieces”, Bart continues. “One of the essential components was the accumulator, weighing over 8 ton, installed at height of 100 meters above sea level! This component is part of the system which keeps the drill string isolated from the ships heaving during drilling operations. We also removed the crown block, gripper heads of the BOP guide system, mainboom and valves of the knuckle boom crane. The team also removed sizable hydraulic cylinders from the ships knuckleboom crane, to allow for close inspection and replacement of seals. To conclude this second phase, the Wagenborg Foxdrill team assisted with removal of the topdrive . Upon completion it was prepared for inspection ashore.” After the various pieces of equipment were removed and lowered, the Wagenborg Foxdrill team was demobilised. Various OEM’s and other parties were involved to carry out detailed maintenance and overhaul of the drilling equipment ashore. This took several weeks to complete at specialised facilities in Port Elizabeth.

Reinstallation and recommissioning

Once the equipment was again ready for service and brought back on board. Bart explains: “Wagenborg Foxdrill mobilised a third team to take care of lifting, rigging and reinstallation of the equipment. This third phase involved a rope access team of four man working in dayshift, led by supervisor Bart Poorthuis. Over the course of a two week period and in close cooperation with Saipem crew and OEM specialists, a variety of cylinders, pipe handling equipment, drilling equipment and other key components were reinstalled and recommissioned.”

Upon completion of the third phase, the Saipem 12000 Drillship set sail for its next drilling campaign at an offshore location at a significant distance off the coast of Mozambique. “During this sea voyage, the team - led by Patrick Brookhuis - carried out an inspection to verify closeout of finding from the earlier performed Dropped Objects Survey. Foxdrill inspects and reports according the global DROPS guidelines”, tells Bart. DROPS is essentially a Global Work Group, represented by 200 operators, contractors, service companies and industry bodies, all sharing commitment and for the common goal of preventing any (potentially harmful) dropped objects.

Priority

Later on, during this fourth and final phase, Wagenborg Foxdrill was contacted by the Saipem project team with a priority request. “Saipem wanted us to provide support in aligning the derrick’s guide tracks”, Bart continues. “These tracks support lateral movement of drilling equipment in the derrick and absorb the torque exerted by the ships topdrive on the drill string. This can extend up to several 1000 meters through ocean and into the earths subsea surface. We were able to mobilize a specialised surveyor within a couple of days. With measurements carried out in cooperation with the rope access team and by installing shim plates where required, it was assured that the structure was fully aligned once again, thereby supporting accurate drilling and reducing wear and tear in the installation.”

Upon arrival at the new drilling site, Saipem and Foxdrill had successfully completed the planned scope of work and the drillship Saipem 12000 was ready to commence drilling for its client ENI.

About Saipem

Saipem is a leading company in engineering, drilling and construction of major projects in the energy and infrastructure sectors. It is “One-Company” organized in five business divisions (XSIGHT, dedicated to conceptual design, Offshore E&C, Onshore E&C, Offshore Drilling and Onshore Drilling). Saipem is a global solution provider with distinctive skills and competences and high-tech assets, which it uses to identify solutions aimed at satisfying customer requirements. Listed on the Milan Stock Exchange, it is present in over 70 countries worldwide and has 32,000 employees of 120 different nationalities.